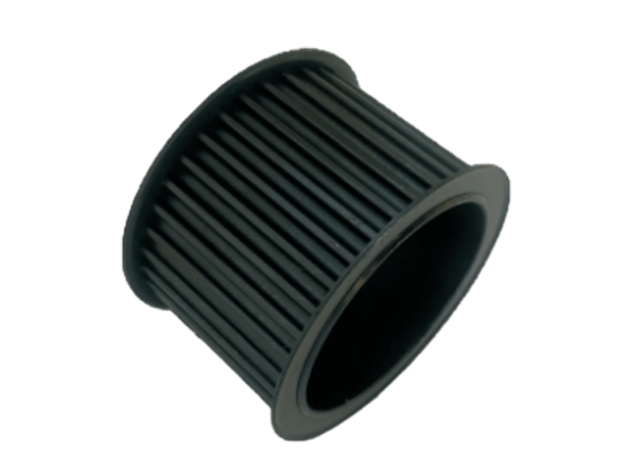

RECOMMENDED PRODUCT

The gears and sprockets sold by our company have been recognized and praised by new and old customers. We sincerely welcome customers at home and abroad to work together to create a brilliant future.

HONGRUI MACHINERY HONGRUI MACHINERY HONGRUI MACHINERY HONGRUI MACHINERY HONGRUI MACHINERY HONGRUI MACHINERY HONGRUI MACHINERY HONGRUI MACHINERY MACHINERY HONMACHINGI MACHINERY RUGRUINY

YOUR PARTS YOUR PARTS YOUR PARTS YOUR PARTS YOUNG PARTS YOUNG PARTS YOUR CHILDREN

Marine carton machinery

PROFESSIONAL MANUFACTURER OF GEAR

Professional manufacturer of gears and sprockets

Renqiu Hongrui Machinery Parts Co., Ltd. produces industrial sprockets, gears, bevel gears, couplings, racks, chains, shafts and other industrial equipment transmission parts. ANSI, DIN, COMBAT standards and other industrial sprockets are in sufficient stock. The factory was established in 2003, covering an area of 2000 square meters. The implementation of comprehensive quality inspection, the quality system is perfect, with CNC lathe, gear hobbing machine, broaching machine, sawing machine, tapping machine, machining center and other 32 sets of equipment. There are 43 employees. 16 technical and management personnel.

Selected Raw Materials

Gear rack processing using C45/20Crmnti, 40Cr and other high strength fine structural steel material refined. High precision is not easy to wear, high resistance to strength, more durable, beautiful surface anti-rust.

Professional processing and manufacturing

The gear adopts normalizing, quenching and tempering, tooth making, carburizing and quenching, grinding and other processing production processes. Improve wear resistance, improve accuracy, increase strength, and extend service life.

Complete processing technology

Hongrui Machinery has a full range of manufacturing processes such as gear hobbing, gear shaping, and gear grinding, which can ensure the gear rack tooth profile, tooth radial runout, tooth pitch deviation, tooth surface finish, etc.

HONG RUI

BLOG & NEWS

Timely understanding of News, better choice of our products!

2025-03-27

Sprockets in the Spotlight: Innovations and Insights

2025-03-22

Sprockets: The Unsung Heroes of Industry Dynamics

2024-11-27

Types and specifications of standard component sprockets

2024-11-27

Application fields of bevel gears

GLOBAL NETWORK

Global services for customers

Service from40of a country300Multiple customers

The diversified marketing model has established a perfect sales and service system, and the products are exported to more than 40 countries and regions such as Russia, Mexico, Peru and Spain. We are committed to the development of enterprises with excellent services and products.

Select small samples of products that meet your needs and test them until they are qualified.

Or you provide samples we send after proofing

Until the quality is confirmed to be qualified

Support customization

Years of customization experience, support to map to sample customization

Focus on quality

Own factory, focus on quality and strict quality inspection

Timely shipment

After confirming the plan, arrange production and delivery in time.

After-sales worry-free

24 hours online, solve your problems in time